There is no one denial to the fact that civil engineering has been among those oldest and at same time most distinct medium occupation in human society. It is used for constructing many structures like houses, schools, hospitals and the likes. One of these is concrete, which provides the backbone to just about every construction project and is typically formulated through components such as water and a mixture of sand plus cement. This new variety of concrete is fiber concretes which experts utilize throughout metropolitan advancement endeavors.

Modifying the mixture is a single thing that it classifies fiber concrete: for example, adding of small fibers (normally glass,steel or plastic). This newly discovered type of concrete is much tensile and strongest that traditional ones. It also comes with a lot of other benefits that have popularized this choice amongst builders.

The tensile strength of concrete is greatly improved with the new invention by adding fibrous materials in fiber concrete. This is where these fibers, when added and mixed with the concrete, come to help significantly by strengthening it. As a result, the concrete is no longer easily split or cracked under high pressure - an important characteristic for construction in terms of strength.

Furthermore, the fibers in fibre concrete are also easier to process. With tougher structural concrete, the slender and lighter structures can be constructed. As a result, the reduction of materialization in construction considerably reduces both time and resources for any building work undertaken but also leads to huge savings.

Concrete Industry Greater Strength And Durability With Fibre Reinforcement

The fiber could already be a revolution for the steel Industry Concrete, which used to build construction with sand, water and cement in its manufacturing leaving buildings under equipped. Fiber reinforcement however entirely altered this by tangibly enhancing the tensile strength and resilience of concrete.

Finally, the fiber reinforcement has given designers a free-pass to construct buildings that were previously though difficult and cumbersome. Fiber concrete can simply be used to create domes or curved walls, thanks already been reinforced with fibers and thus making it more capable of being bent.

A fiber concrete made from recycled materials offers a sustainable alternative for the future. This type of concrete frequently includes fibers, which are made from either recycled plastic or steel and therefore save waste to landfill.

This tensile strength combined with the longevity of fiber concrete means it will not need to be replaced as often due to wear and tear, compared with traditional concretes. This robustness saves time and money for builders who did not have to replace tanks as often, but also valuable resources in the long run.

Cast fibers are a frequent choice for projects in concrete surfaces, improving thickness and also tensile strength. A Housing Project, Habitat 2000 in South Africa built more resistance and durable housing easier access for people thro fibre concrete. Two of these are the prefabricated houses constructed in reinforced concrete, which is capable to withstand any weather condition and still operate.

In the case of Nanjing Green Towers, planted into two large scale urban buildings in China which will be made from fiber concrete / ByCONCEPT. Thats why its adaptability to structurally perform with exclusive shapes and designs makes fiberReinforced concrete metarial very special.

Fiber concrete is a new method of construction, which provides improved strength and resilience over standard concrete through the use of fibers. Because the fibers are mixed in with concrete it becomes an incredibly durable material, capable of absorbing high degree pressure without any lasting damage. In short, environmental stewards are taking a closer look at fiber concrete pipes and liking what they see quickly saving build time while being ecologically friendly.

Shanghai Eco-Arch places quality control at heart of its manufacturing philosophy. realize the necessity durability and reliability in construction materials. That's why have enacted fiber concrete quality control procedures every phase of production. modern manufacturing facilities test products like Fiber Cement Boards and Translucent Concrete performance safety. Every product is subjected exhaustive inspection determine dimensions, color and structural quality. It this way that every item leaves our factory in pristine state. Eco-Arch's commitment to quality offers customers peace of mind that they're investing products that combine quality workmanship with incredible durability.

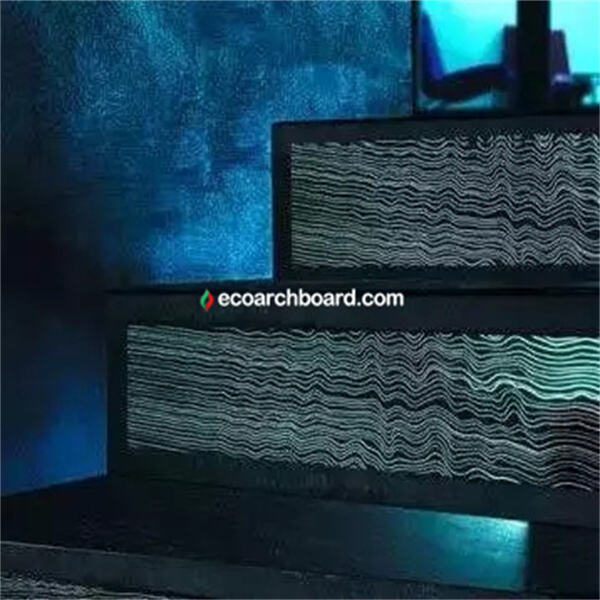

Shanghai Eco-Arch leverages over 11 years expertise in R D innovations lead the green building materials market. extensive experience reflected in broad product line comprising Artistic Gilt Wall Panels, Gilt Sandstone Cement Boards Flexible Ceramic Tiles, 3D Travertine Soft Stones. team engineers' designers continuously push boundaries of science and technology incorporating sustainable practices the fiber concrete technology into our products. dedication innovation ensures that products aren't just up to standards of industry, but they also surpass them, offering exceptional durability, aesthetic appeal and environmental advantages. Eco-Arch is a partner who is committed to providing cutting-edge solutions for modern construction. This is backed with over 100,000 successful examples of cooperation across the world.

Shanghai Eco-Arch a leader in providing tailored solutions satisfy the requirements of each client. This a sign our dedication providing personalized experience. range more than 3,000 high quality items such as Artistic Gilt Wall Panels as well as Flexible Ceramic Tiles and Concrete Boards can customized meet needs of any needs project. take pride understanding clients' unique needs, offering free samples and 24/7 professional OEM and ODM services fiber concrete an easy customized experience. one-stop approach we employ means take care of every aspect of the customization process deliver bespoke products align perfectly with your vision for project. Eco-Arch's customization is more just a solution. We guarantee custom-designed excellence that improves both the aesthetics and functional aspects of your construction project.

Shanghai Eco-Arch's massive production capacity designed to meet the demands for projects of any size, ensuring timely delivery a consistent supply. Our manufacturing facilities produce huge quantities building products such as 3D Travertine Soft Stones and Translucent Concrete without compromising quality. The capacity robust and has supported over 100,000 cooperation cases date, enabling us serve fiber concrete and domestic markets efficiently. extensive production and optimized procedures ensure a consistent flow of products. This allows us to reduce the length time required to complete your project on course. Whether you're embarking on one of our small residential developments or a huge commercial construction project Eco Arch's production capacity ensures that you have the materials you need, at the time you require them, and in the highest quality and dependability that are the hallmarks of Eco-Arch's brand.